MACHINING

SINGLE POINT DIAMOND TURNING

Single Point Diamond turning is a process of mechanical machining of precision elements using lathes or derivative machine tools (e.g., turn-mills, rotary transfers) equipped with natural or synthetic diamond-tipped tool bits. The term single-point diamond turning (SPDT) is sometimes applied, although as with other lathe work, the "single-point" label is sometimes only nominal (radiused tool noses and contoured form tools being options).

Single Point Diamond turning is a process of mechanical machining of precision elements using lathes or derivative machine tools (e.g., turn-mills, rotary transfers) equipped with natural or synthetic diamond-tipped tool bits. The term single-point diamond turning (SPDT) is sometimes applied, although as with other lathe work, the "single-point" label is sometimes only nominal (radiused tool noses and contoured form tools being options).

SINGLE-POINT DIAMOND TURNING MACHINE

Latest generation of the most user friendly compact ultra-precision CNC diamond turning lathe. Used for the rapid production of spherical & aspheric optical lenses, mirrors, mold inserts, freeform optics, and even mechanical components.

Latest generation of the most user friendly compact ultra-precision CNC diamond turning lathe. Used for the rapid production of spherical & aspheric optical lenses, mirrors, mold inserts, freeform optics, and even mechanical components.

DIAMOND POINT TURNING

Diamond point turning is a multi-stage process. Initial stages of machining are carried out using a series of CNC lathes of increasing accuracy. A diamond-tipped lathe tool is used in the final stages of the manufacturing process to achieve sub-nanometer level surface finishes and sub-micrometer form accuracies

Diamond point turning is a multi-stage process. Initial stages of machining are carried out using a series of CNC lathes of increasing accuracy. A diamond-tipped lathe tool is used in the final stages of the manufacturing process to achieve sub-nanometer level surface finishes and sub-micrometer form accuracies

SINGLE POINT DIAMOND TURNING

Single Point Diamond Turning (SPDT) centers produce superior optical surface finishes and consistent performance in plastic and metals. Vertically integrated with Optical and Mechanical Engineering, SPDT, Optical Molding, Metrology and testing.

Single Point Diamond Turning (SPDT) centers produce superior optical surface finishes and consistent performance in plastic and metals. Vertically integrated with Optical and Mechanical Engineering, SPDT, Optical Molding, Metrology and testing.

MOORE NANOTECH

Moore Nanotech : Established in 1997, our abbreviated name Nanotech was from the beginning not only our registered trademark, but also a symbol of our commitment to developing highly advanced equipment and manufacturing processes capable of achieving nanometer level surface accuracies on advanced optical components. Our ultra-precision machining systems support many industries including consumer electronics, defense, aerospace, lighting, medical, automotive, and ophthalmic. Our world-class team of specialists has dedicated their careers to this technology, and their vision has made Nanotech the fastest growing company in this field.

Moore Nanotech : Established in 1997, our abbreviated name Nanotech was from the beginning not only our registered trademark, but also a symbol of our commitment to developing highly advanced equipment and manufacturing processes capable of achieving nanometer level surface accuracies on advanced optical components. Our ultra-precision machining systems support many industries including consumer electronics, defense, aerospace, lighting, medical, automotive, and ophthalmic. Our world-class team of specialists has dedicated their careers to this technology, and their vision has made Nanotech the fastest growing company in this field.

Moore Nanotechnology Systems

Moore Nanotechnology Systems, LLC (Nanotech®) is dedicated to the development of ultra-precision machining systems and their successful utilization through the formation of lifelong customer partnerships. Total customer satisfaction of our products and services has always been, and will continue to be, our highest priority as we support our customer's expansion into new markets through the design and development of new products, complimentary machine accessories, and enhancements to our existing products

Moore Nanotechnology Systems, LLC (Nanotech®) is dedicated to the development of ultra-precision machining systems and their successful utilization through the formation of lifelong customer partnerships. Total customer satisfaction of our products and services has always been, and will continue to be, our highest priority as we support our customer's expansion into new markets through the design and development of new products, complimentary machine accessories, and enhancements to our existing products

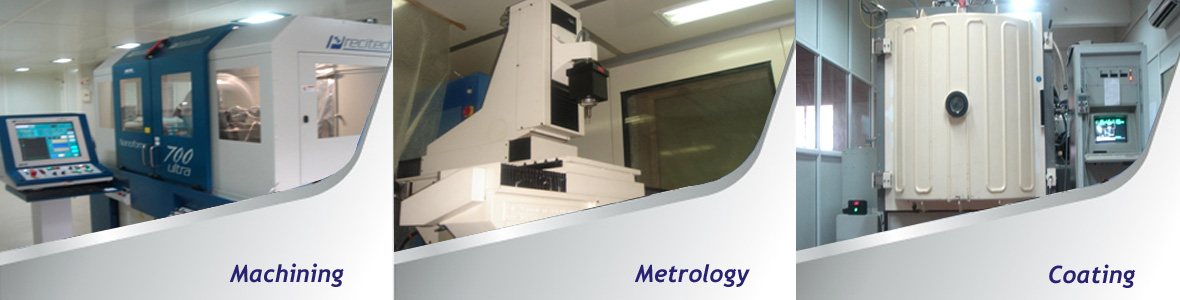

AMETEK PRECITECH MACHINES

AMETEK Precitech designs and manufactures ultra precision machining solutions for freeform diamond turning, milling, and grinding which are used to produce optical lenses, mold inserts, mirrors, and precision mechanical components. Our AMETEK Precitech machines produce rotationally symmetric, asymmetric, freeform, and sculpted geometries with form tolerances in the sub-micron range and nanometer surface finishes.

AMETEK Precitech designs and manufactures ultra precision machining solutions for freeform diamond turning, milling, and grinding which are used to produce optical lenses, mold inserts, mirrors, and precision mechanical components. Our AMETEK Precitech machines produce rotationally symmetric, asymmetric, freeform, and sculpted geometries with form tolerances in the sub-micron range and nanometer surface finishes.

DIAMOND TURNING

|

|

|

| NANOTECH 350 | NANOFORM 700 ULTRA | NANOFORM 250 |

Mechvac offers in-house single point diamond turning services on its Moore Nanotechnology Systems 700 Ultra Precision Lathe, one of the most accurate lathes available today.

Our ultra-precision machine systems support single point diamond turning machines.

CNC Optical GRINDING

|

|

| SM 80 CNC Optical Grinding machine | MCG 100 CNC Optical Grinding machine |

CNC Optical Grinding machine features

Working Range Diameter - Ø 10 - 200 mm spherical

Working Range Diameter - Ø 10 - 200 mm aspherical

Working Range Radius - 5 mm - ∞

CNC Optical Polishing

|

|

| SPO 80 CNC Optical polishing machine | ASP 200 CNC Optical polishing machine |

The new OptoTech polishing machine SPO 80 CNC is the low Cost High Speed Polishing Machine. The universal working range, easy handling combined with the most modern polishing technology offer an up to date alternative to the well introduced OptoTech SPO 80.

CNC Optical polishing machine features

Working Range Diameter :

Ø 10-250 mm (Asphere Mode)

Ø 10-120 mm (SynchroSpeed Mode)

Working Range Radius :

10 mm - ∞ (Best Fit Radius)

CENTERING AND EDGING

|

|

| LOH LZ80 (With Laser) | WZM 150 CNC |

Working Range Ø 10 to 150 mm

Tool Ø 120 to 180 mm

Cutting Speed 0 to 30 m/s Variable Speed